Đăng ký nhận bản tin của chúng tôi và luôn là người đầu tiên nghe về những gì đang xảy ra.

Market Application and Processing of Mica

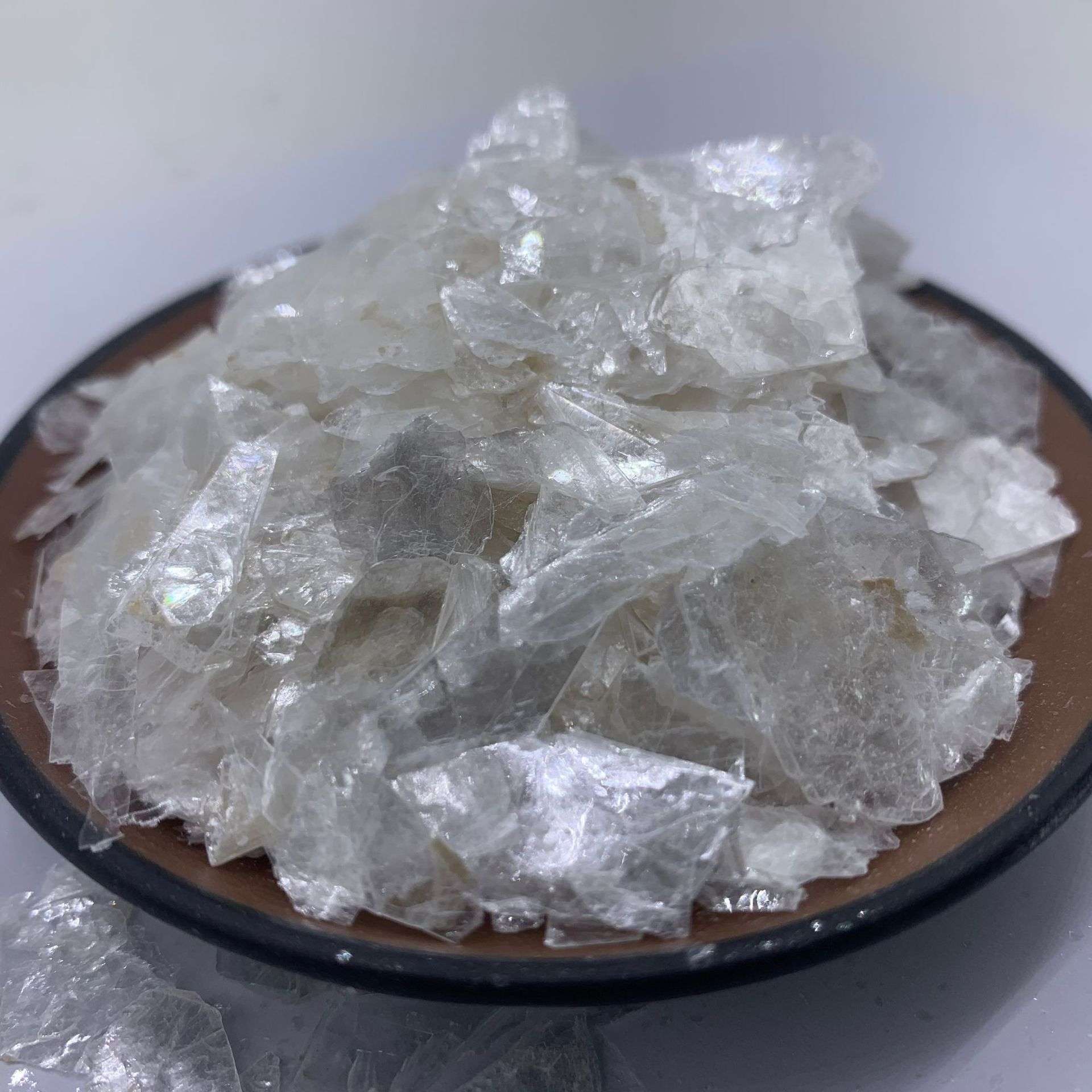

Aug 23, 2024Mica is an important industrial mineral with a layered structure and good physical and chemical properties, so it has a wide range of applications in many fields. There are many types of mica, including but not limited to muscovite, phlogopite, biotite, lepidolite, etc. Each type of mica has its own specific composition and properties, which determines their application in different fields.

Mica belongs to the layered structure of the monoclinic system, and its chemical formula is KAl2(AlSi3O10)(OH)2. Its hardness is generally between 2.5-4, and its specific gravity is about 2.77-2.88g/cm³. Mica crystals are usually plate-shaped pseudo-hexagonal, transparent to translucent, with a very complete set of bottom cleavage, so they can be easily peeled into thin sheets. These thin sheets have significant elasticity and toughness, and can be bent to a certain extent without breaking easily.

Mica minerals can be divided into three subgroups according to chemical composition and optical characteristics: muscovite subgroup, biotite-phlogopite subgroup and lepidolite subgroup. The color can range from colorless to white, and sometimes it can appear light yellow, light green or light red. Its luster is similar to glass or pearl, so it will have a similar effect when observed at a certain angle. In addition, mica has strong insulation and heat resistance, and can maintain stable performance under high temperature conditions, which makes it particularly important in the electronics and electrical industries.

The main chemical components of mica include aluminum oxide (Al2O3), iron oxide (Fe2O3), potassium oxide (K2O), etc. In addition to these main elements, mica may also contain trace amounts of sodium, magnesium, iron, lithium, etc., as well as water and oxides. These chemical components give mica different physical properties, such as electrical insulation, heat resistance and chemical stability.

The global distribution of mica mineral resources is relatively wide, and the main production areas include

India: India is rich in mica mineral resources, especially in Bihar and Andhra Pradesh, where there are a large number of mica mines.

Russia: Russia's mica resources are also very rich, especially in Siberia.

China: China's mica resources are mainly distributed in Xinjiang, Sichuan, Inner Mongolia and other provinces, especially in Xinjiang Altai, Sichuan Danba and Inner Mongolia Tuguiwula.

Madagascar: This African island country is also an important producer of mica, especially in its northern region.

Brazil: Brazil's mica resources are mainly concentrated in the southeastern region.

Argentina: Argentina also has certain mica mineral resources.

The market application of mica is very wide, including but not limited to the electronics industry, building materials, automobile manufacturing, power equipment, cosmetics, fireproof materials, etc. The application of mica in these fields not only reflects its excellent physical and chemical properties, but also reflects its irreplaceable importance in modern industry and daily life.

Electronic Industry

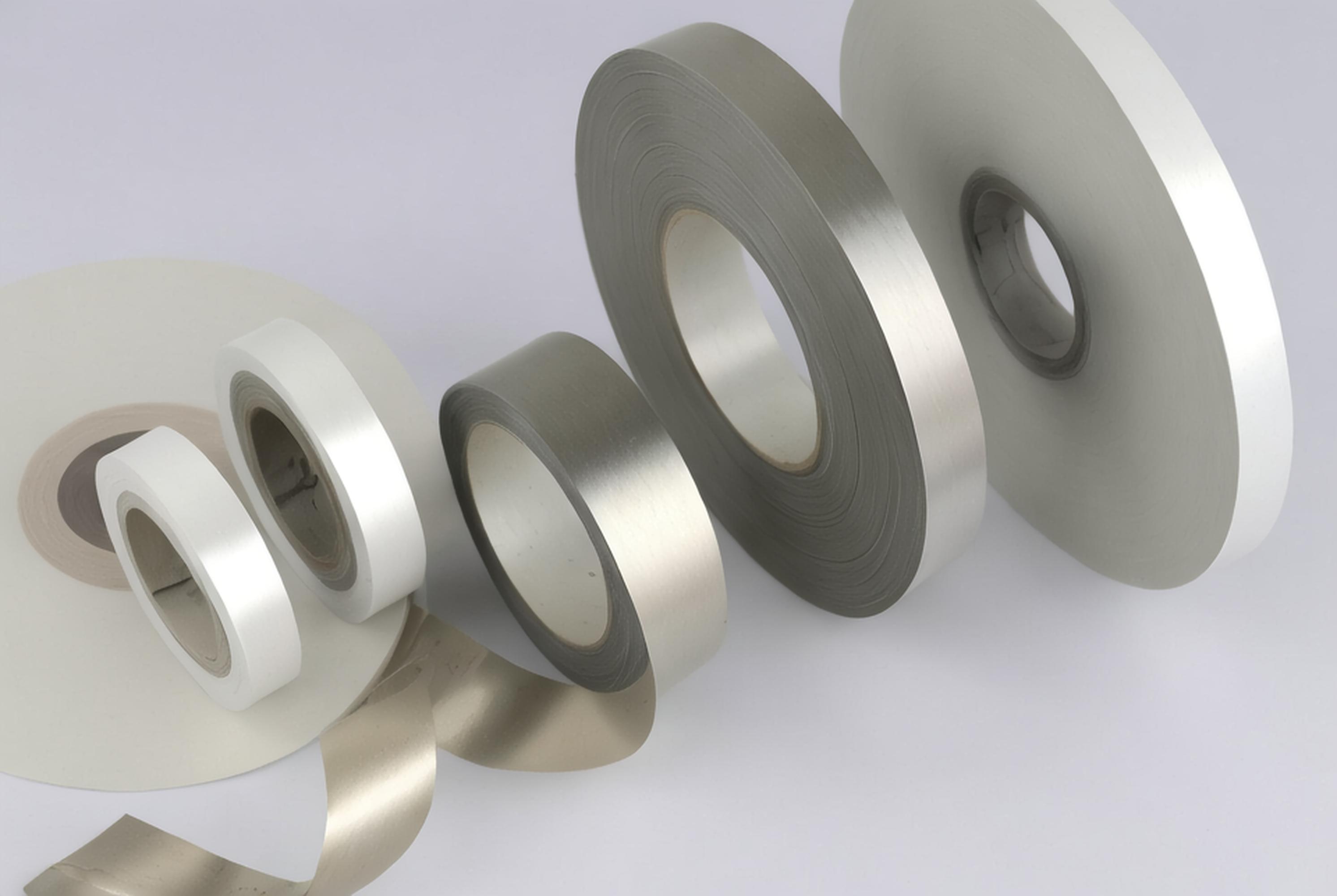

In the electronics industry, mica is used as a high-frequency insulation material, especially in high-frequency circuits, where mica has a small dielectric loss and can effectively reduce signal loss. In addition, mica is also used to make printed circuit boards because it can withstand high temperatures without losing its insulation properties.

Building Materials

In the construction industry, mica is used as an efficient thermal insulation material, which can prevent energy loss caused by the temperature difference between the inside and outside of the building. Mica also provides additional fire protection because its layered structure can prevent the spread of flames.

Automotive Manufacturing

In automotive manufacturing, mica is used as part of the body material to improve the heat resistance and safety of the vehicle. Mica can also be used in brake pads to improve its heat resistance and reduce the heat generated by friction.

Power Equipment

In power equipment, mica is used as an insulating material, especially for transformers, cables and other power equipment. Mica's high heat resistance and chemical stability make it ideal for these applications.

Cosmetics

In the cosmetics industry, mica is used as a brightening ingredient to make products look more shiny. In addition, mica's flaky structure helps fill in skin lines and make the skin look smoother.

Fireproof Materials

In fireproof materials, mica is used as an effective thermal insulation and fire-resistant material. Mica's multi-layered structure can reflect heat back, thereby reducing the damage caused by fire.

Complete mica processing involves a series of process flows from the mining, sorting, crushing, grinding of raw ore to the final mica products. This time we will briefly introduce the three links of crushing, sorting and grinding.

Crushing

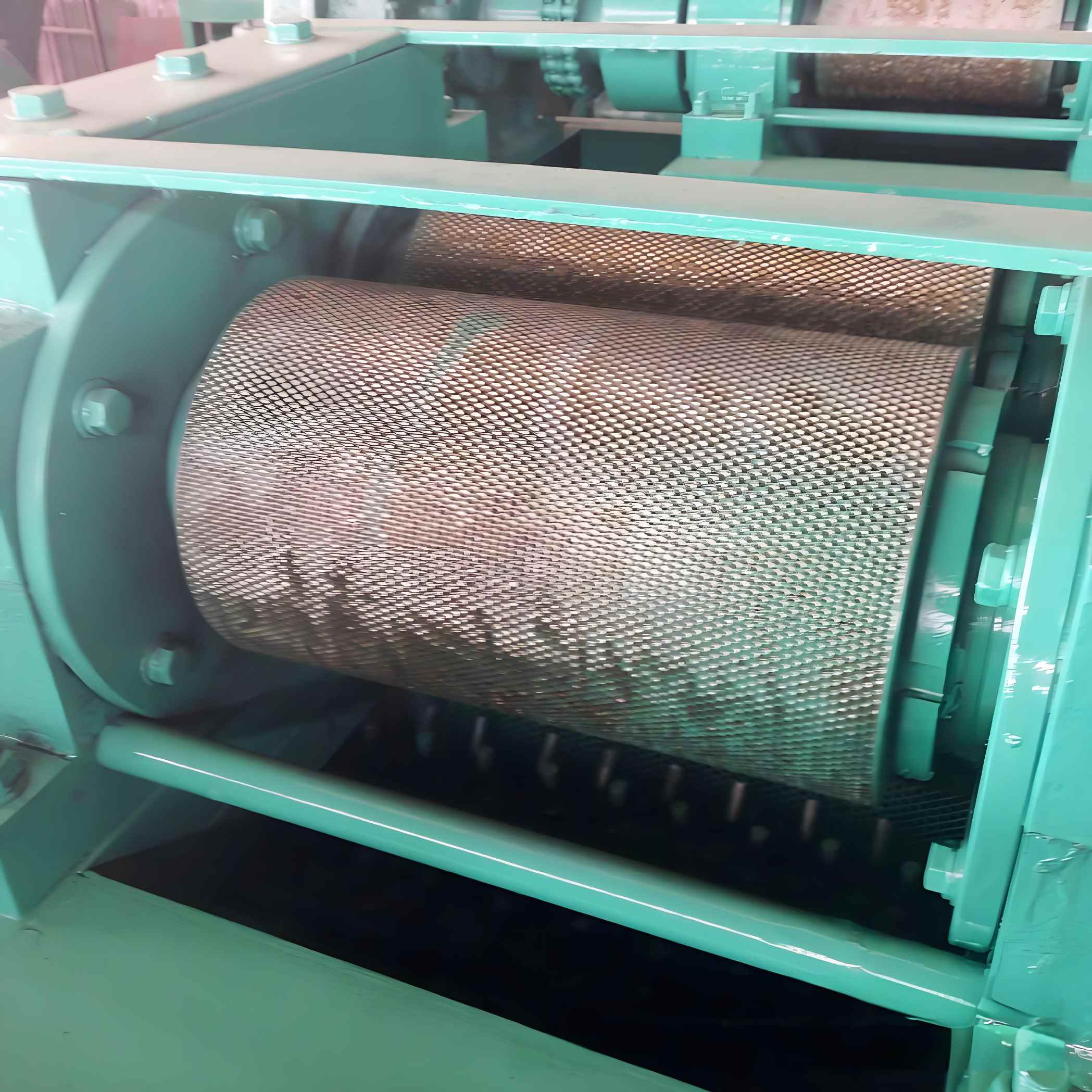

The crushing of mica ore is an important link in the mica processing process, which directly affects the subsequent processing and application performance of mica. At present, the main crushing equipment on the market includes jaw crusher, roller crusher, cone crusher and other types, each of which has its specific application scenarios and advantages.

The roller crusher plays an important role in the crushing of mica ore. It has the advantages of high crushing ratio, strong processing capacity, low maintenance cost, and precise control of finished product particle shape. By adjusting the roller spacing and crushing pressure, the discharge particle size can be effectively controlled to ensure the integrity of the mica sheet, which is conducive to improving the quality and application value of the product.

Jaw crushers are often used in the crushing of lithium mica ore, especially for the initial crushing of large pieces of raw ore, crushing the ore to a suitable feed fineness, creating conditions for subsequent processing.

Water jet mill crushing technology is a new type of mica crushing method. It cuts and crushes the material through high-speed jet water flow. It has the advantages of high crushing fineness, high precision, less dust generation and less wear on equipment.

The crusher for mica production with a multi-stage crushing structure prepares for later processing through multi-angle crushing to improve work efficiency.

The crushing process of mica ore usually includes the mining and screening of raw ore, crushing, screening and grading, and air separation. The specific process includes the use of a jaw crusher for primary crushing, followed by secondary crushing with a roller crusher, and finally a particle size screening by a screening machine to achieve the required particle size distribution.

What needs to be paid attention to during the crushing process is the selection and parameter setting of the crushing equipment, as well as the screening and separation effect after crushing. For example, although the water jet mill crushing mica technology has many advantages, it also has the problems of high equipment cost and narrow crushing particle size range, and the mica mineral needs to be pretreated.

Sorting

The sorting technology of mica is a key link in the processing of mica ore, which is directly related to the quality and output of mica products. The methods of mica sorting mainly include hand sorting, gravity sorting, magnetic separation, flotation and photoelectric sorting.

Hand sorting is the oldest and most direct sorting method, which is suitable for the sorting of large mica. Workers can directly pick out the separated mica on the mining face or ore pile.

Gravity separation is a method of sorting using the difference in mineral density, which is suitable for coarse-grained mica. Commonly used gravity separation equipment includes jigs, shaking tables and spiral chutes.

Magnetic separation is a method of sorting using the difference in mineral magnetic properties, which is mainly used to sort mica containing iron impurities. Magnetic separation equipment mainly includes dry magnetic separators and wet magnetic separators.

Flotation is a method of sorting using the difference in physical and chemical properties of the mineral surface. It is currently the most widely used sorting method and is suitable for fine-grained mica. During the flotation process, attention should be paid to factors such as the selection and dosage of reagents, flotation time and concentration.

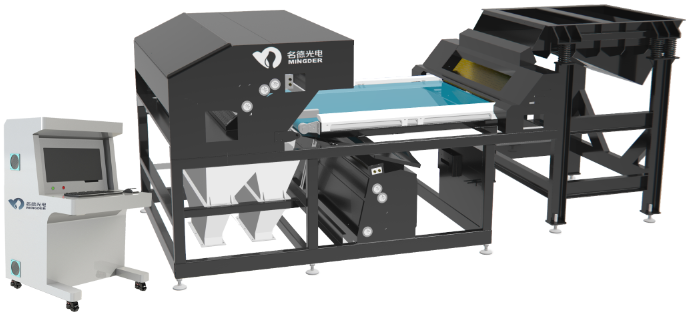

Mica photoelectric sorting technology is a technology that uses optical and electrical properties to classify mica ores. This technology is mainly used in the field of ore processing. By identifying the differences in surface characteristics such as color, texture, and gloss between mica and other minerals, effective separation of mica is achieved. With the continuous advancement of science and technology, photoelectric sorting technology has been widely used in the mining field, especially in the beneficiation process of mica ores, showing significant advantages. Compared with other sorting methods, photoelectric sorting has the characteristics of high efficiency, low cost, environmental protection and high intelligence level.

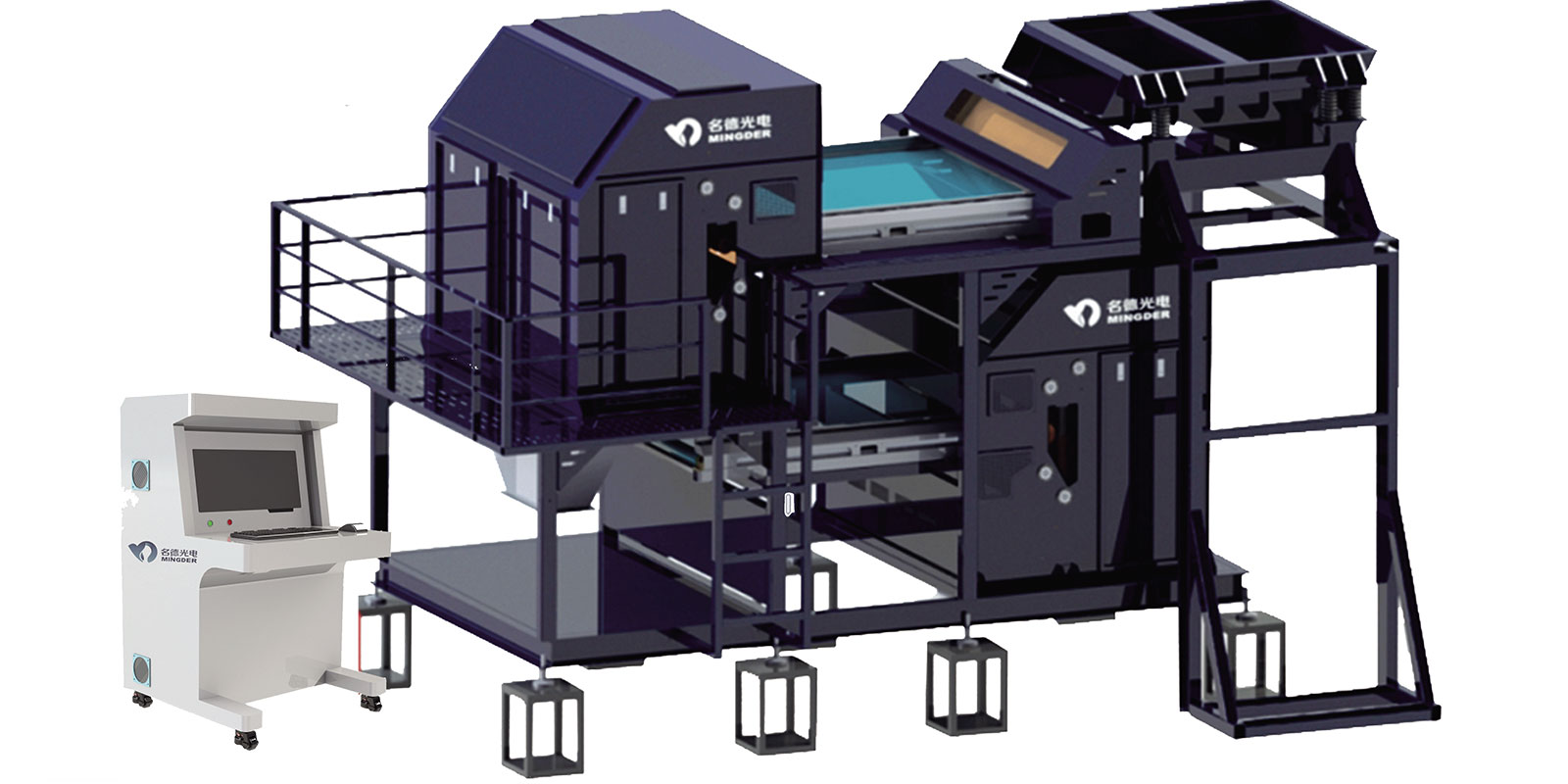

Single-layer AI Ore Sorting Machine

In practical applications, photoelectric sorting technology has been proven to effectively improve the beneficiation efficiency of mica ore. For example, Mingde Optoelectronics' photoelectric sorting equipment has achieved high-precision identification and sorting on multiple metal and non-metallic minerals, including lithium mica, spodumene, barite, etc.

Double-layer AI Ore Sorting Machine

Hefei Mingde Optoelectronics Technology Co., Ltd. has introduced AI and big data technology in the field of photoelectric sorting. The AI intelligent sorting machine launched can accurately extract the surface characteristics of mica ore and realize the accurate sorting of ore and impurities.

Grinding

The grinding process is carried out after flotation is completed, with the purpose of further refining the mica after flotation to the required particle size. The grinding process usually includes two stages: primary grinding and secondary grinding. By adjusting the grinding medium and time, the fineness and uniformity of mica particles can be effectively controlled. There are two main methods for mica grinding: dry and wet, each of which has its own characteristics and applicable occasions.

Dry grinding refers to grinding without adding any liquid. This method is simple to operate and has low cost, but due to the lack of lubrication, the heat generated by grinding may cause damage to the mica crystals, affecting its flaky structure and exfoliation. The equipment commonly used for dry grinding includes Raymond mills, ball mills, etc.

Wet grinding is to add an appropriate amount of water or other liquids during the grinding process to protect the mica crystals through liquid lubrication and cooling, reduce heat accumulation, and thus protect the structure of the mica from being destroyed. Wet grinding can obtain mica powder with higher purity and better exfoliation, but it requires an additional drying step, and the equipment investment and energy consumption are relatively high.

The processing quality of mica powder is directly related to the performance of the final product, so it is particularly important to choose a suitable mill. The selection of the mill needs to consider the characteristics of mica and the required fineness, purity and other requirements.

Key points for selecting a mill

Type of mill: According to the physical and chemical properties of mica, as well as the required fineness and purity, you can choose a high-pressure mill, a vertical mill, an ultrafine mill, etc.

Grinding efficiency: An efficient mill can improve production efficiency and save energy costs. For example, some grinding mills can increase production by more than 40% through optimized design, while saving 30-40% of electricity consumption costs.

Environmental performance: Modern grinding mills emphasize environmental performance and are equipped with pulse dust collectors and other equipment to achieve efficient dust removal and meet environmental protection and noise reduction requirements.

Product specifications: The grinding mill should be able to produce mica powder specifications that meet the requirements, such as 325 mesh, 600 mesh and other different finenesses.

Process adaptability: The grinding mill should be able to adapt to different grinding processes, such as dry and wet methods, and whether special processes such as acid treatment are required to improve the whiteness of mica powder.

Specific equipment recommendation

High-pressure grinding mill: Suitable for large-scale production, high-pressure suspension roller grinding mills and other models can be provided, suitable for processing mica ores with higher hardness.

Vertical grinding mill: Suitable for large-scale production, with high efficiency and low energy consumption, the product particle size can be adjusted to meet different needs.

Ultrafine grinding mill: Suitable for the preparation of ultrafine mica powder, can reach micron-level fineness, suitable for application scenarios with strict requirements on fineness.

Airflow mill: suitable for dry grinding, crushing mica through high-speed airflow, suitable for preparing ultrafine powder.

This is the introduction of mica. In short, as a multi-purpose mineral, mica is not only widely used in industry, but also plays an important role in scientific research and life. With the development of processing technology and different innovations of new technologies, the application prospects of mica will become broader and broader.