Đăng ký nhận bản tin của chúng tôi và luôn là người đầu tiên nghe về những gì đang xảy ra.

Process flow of high purity quartz sand

Sep 27, 2024High-purity quartz sand refers to quartz powder with a SiO2 content of more than 99.99%, which is an important raw material for making quartz glass. This high-purity quartz sand is widely used in high-end industries such as integrated circuits, solar cells, optical fibers, lasers, aerospace and military.

So how is high-purity quartz sand extracted?

First of all, material selection is the key: quartz stone with a silicon dioxide content of not less than 99.3% is selected as the raw material. After cleaning and removing impurities, the raw material is crushed into 5-15mm particles with a crusher.

Next is the calcination and water quenching process: the crushed particles are calcined at 400-1300 ℃, and then the particles are quickly placed in an ice-water mixture for quenching for 10-20S and then washed, and then soaked in 40-50 ℃ water for 1-3min, taken out and washed with deionized water and dried.

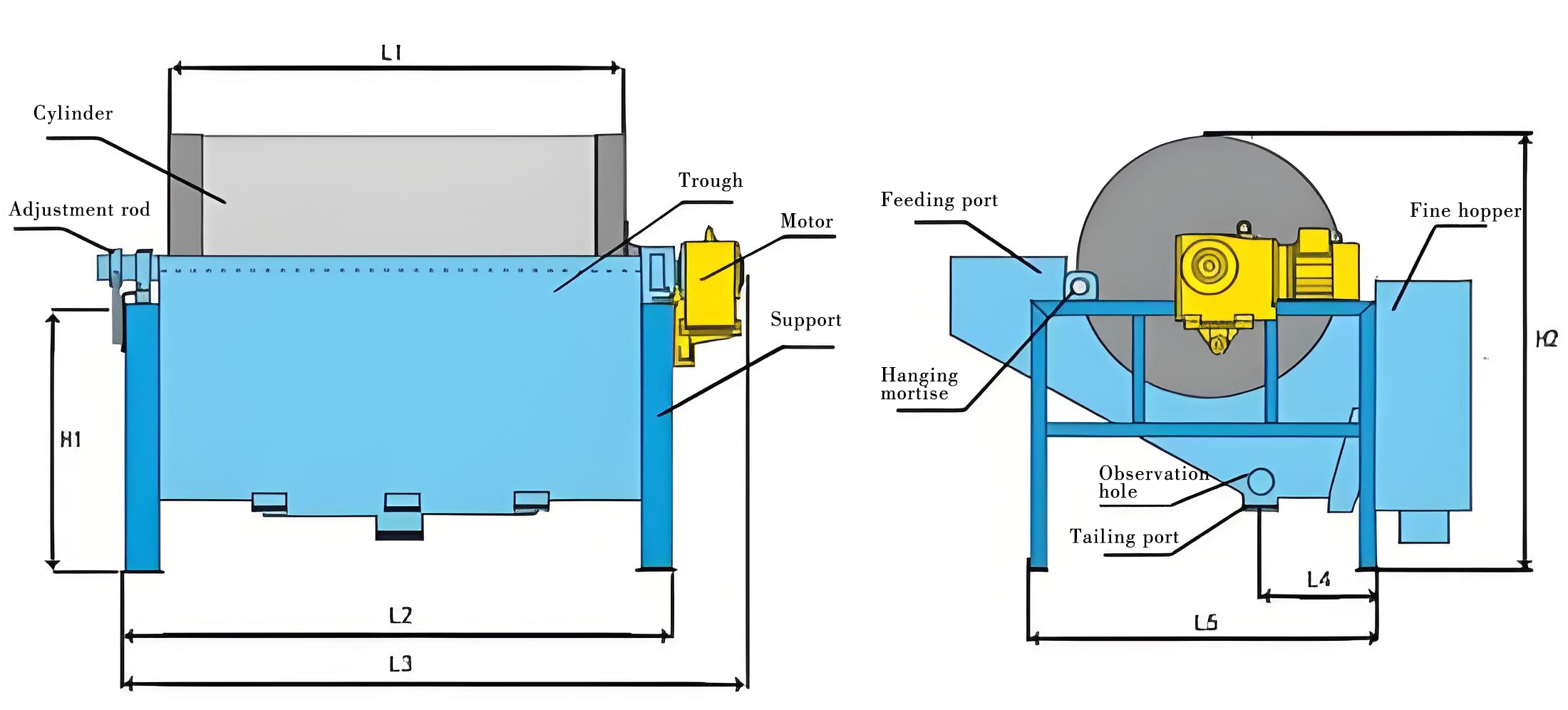

Then there is electric separation and magnetic separation: put the particles into a wet ball mill and grind them to 50-100 mesh, apply a DC electric field of 200-400v/cm at 150-250 ℃ for 1-2h, and then apply a magnetic field strength of 5000-7000GS in a magnetic separator for magnetic separation. Grind the particles after magnetic separation to 150-200 mesh again, apply a DC electric field of 500-700v/cm at a temperature of 300-450 ℃ for 0.5-1.5h, and apply a magnetic field strength of 8000-10000GS in a magnetic separator for magnetic separation again. The collected quartz sand enters the acid washing process.

Pickling treatment: Soak the quartz sand in a hydrochloric acid solution with a mass fraction of 15-25% for 1-3 hours, filter and collect the first filtrate and the filtered quartz sand, dialyze the first filtrate with an anion exchange membrane in a dialysis tank to obtain the recovered hydrochloric acid, rinse the soaked quartz sand with deionized water, add a sodium carbonate solution with a mass fraction of 4-6% and stir for 0.5-0.8 hours. The solid-liquid ratio of quartz sand to sodium carbonate is 1:1.3-1.6, and filter and rinse with deionized water after stirring.

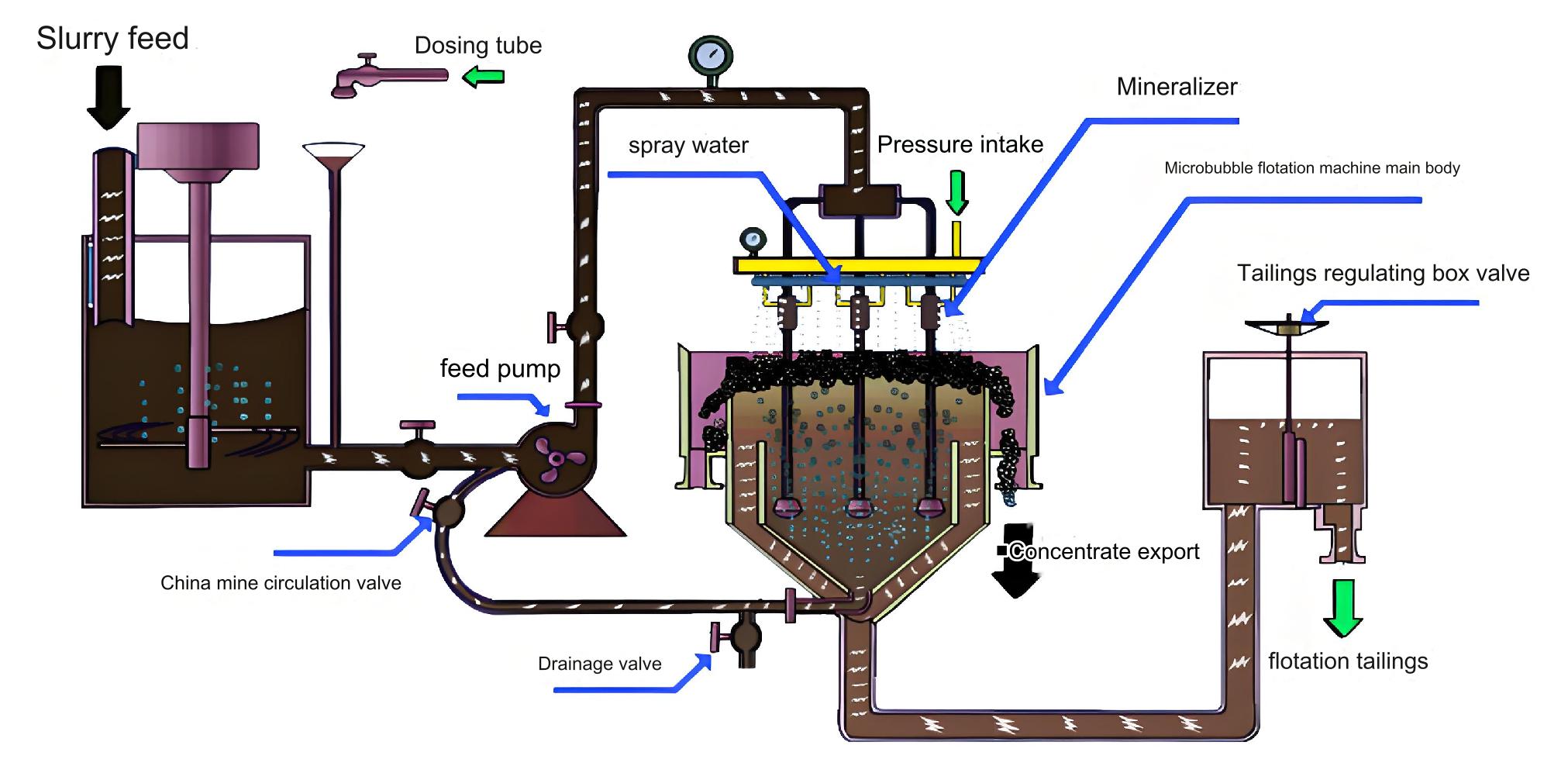

Flotation treatment: Put the rinsed quartz sand into a flotation machine for flotation, add a flotation agent and adjust the pH to 1-3 with hydrochloric acid, the flotation time is 4-6 minutes, and wash the quartz sand with deionized water to neutral after flotation.

Drying treatment: Use a dryer to dry the washed quartz sand at 200-300 ℃ for 4-10 hours, and the water content of the dried quartz sand does not exceed 0.2%.

The high-purity quartz sand obtained after the above process can meet the needs of some high-end industries.