Đăng ký nhận bản tin của chúng tôi và luôn là người đầu tiên nghe về những gì đang xảy ra.

Mingde's AI ore Sorting Tech Made the ore Resources in Northeast of China a Brighter Future

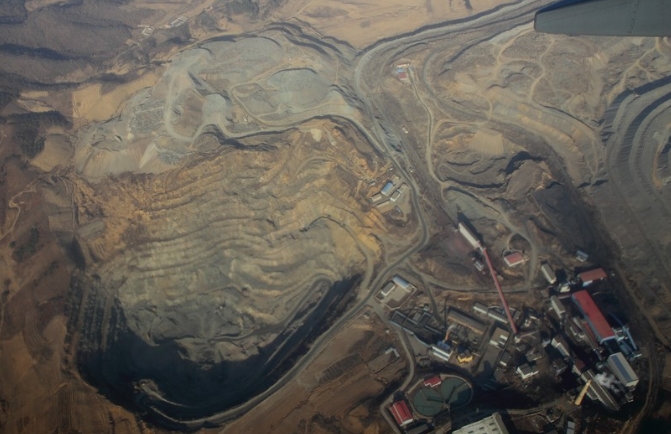

Apr 18, 2025The three northeastern provinces of China (Heilongjiang, Jilin, Liaoning) are not only old industrial bases, but also areas rich in mineral resources, such as the famous Daqing Oilfield discovered in Daqing, Heilongjiang.Although depending on abundant ore resources,the three provinces developed fastly,but due to backward ore sortng tech in the past,it lead to some problems.

How to achieve efficient utilization of resources and promote intelligent transformation of mines through technological innovation has become the core issue of mining development in Northeast China.

一、The High Efficiency Utility Road of ore Resources in Northeast China

The northeast area in China have huge gifts of metalllic ore and non-metallic ore,such as, in metallic ore,Jilin Daheshan Molybdenum Mine and Heilongjiang Yichun Molybdenum Mine are both super large deposits with molybdenum metal reserves ranking among the top in the country.

In non-metallic ore,the reserves of magnesite in Dashiqiao, Liaoning Province account for 25% of the world's total, and it is the core raw material for refractory materials and magnesium metal.

Artificial intelligence sorting equipment is used to sort non-metallic minerals such as talc, brucite, magnesite, calcite, and marble,through multispectral imaging, it accurately identifies the surface texture, texture, luster, and color differences of minerals, with a sorting accuracy of 99%, replacing traditional manual selection and increasing efficiency by more than 10 times.

二、The Industrial Value of Intelligent Transformation

The application of intelligent equipment by enterprises such as Mingde injects new vitality into the development of mining resources in Northeast China, and its value is reflected in three aspects: economic benefits, safety and environmental protection, and resource recycling

(1). Economic benefits: talc ore sorting improves quality and efficiency

Taking Haicheng talc mine in Liaoning Province as an example, traditional manual sorting relies on experience, with large fluctuations in ore grade and high waste rates. After introducing the Mingde Hyperspectral Intelligent Sorting Machine, the sorting efficiency of a single device has been improved to 20 tons per hour by accurately identifying the texture and impurity distribution of talc ore. The whiteness of the concentrate has stabilized from 85% to over 92%, and the waste rate has decreased from 15% to 5%. Only a single production line can save more than 500000 yuan in labor costs annually, increase the added value of high-grade talc exports by 20%, and increase annual income by nearly 5 million yuan or more.

(2). Safety and environmental protection: foreign object sorting reduces operational risks

In the transportation of iron ore and coal, foreign objects such as metal fragments and wood can easily cause the conveyor belt to tear or equipment to jam, leading to production stoppage accidents. The Mingde AI foreign object sorting robot can recognize foreign objects larger than 1cm in real time through 3D vision scanning and deep learning. After introducing this technology, the failure rate of conveyor belts can be reduced by 70%, and the annual maintenance cost can be reduced by more than 3 million yuan, while avoiding fire hazards caused by foreign objects, resulting in significant safety benefits.

(3). Resource recycling: intelligent sorting and reuse of tailings

Mingde Intelligent Sorting Technology achieves precise recovery of non-metallic tailings and associated quartz resources such as talc, magnesite, and magnesite in Northeast China through photoelectric sorting and AI algorithms. For example, the re sorting of tailings from Haicheng talc mine in Liaoning, Panshi magnesite mine in Jilin, and Dashiqiao magnesite mine in Liaoning can reduce the capacity of tailings ponds and the cost of ecological restoration.

三、Future Picture of ore Resources in Northeast China

Relying on resource advantages and technological innovation, the three provinces of Northeast China are shifting from "extensive development" to "lean and intelligent manufacturing".

Next, through technological empowerment, Northeast Mining is expected to become a demonstration highland for efficient resource utilization and green transformation in the country, providing a new engine for the revitalization of old industrial bases.